Boiler water chemistry has a direct impact on boiler efficiency and fuel use.

Improper water treatment will allow scale formation and corrosion. Scale insulates boiler tubes and requires increased fuel use.

Improper water treatment will allow scale formation and corrosion. Scale insulates boiler tubes and requires increased fuel use.

A moderately scaled 250 HP boiler consumes 40% more fuel than the same "clean" boiler.

Corrosion reduces equipment life expectancy and requires capital expenses for repair.

Hydro-Jet Engineering Offer the solutions.

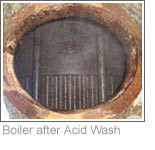

ACID WASH: Hydro-jet offers chemical cleaning service for boilers, Heat Exchangers, Condensers, and Chillers. Boiler Units can be cleaned either by the “circulation or fill and soak Method”

The Circulation Method can be used to clean units with positive liquid flow paths.

ACID WASH: Hydro-jet offers chemical cleaning service for boilers, Heat Exchangers, Condensers, and Chillers. Boiler Units can be cleaned either by the “circulation or fill and soak Method”

The Circulation Method can be used to clean units with positive liquid flow paths.The fill-and –soak method is used for cleaning units with natural circulation. Hydro-Jet Engineering is the longest established and most experience company in Ireland in the field of Boiler maintenance service and acid washing.

BOIL OUT: New Boilers fouled with grease, oils and mill scale should be cleaned by an Alkali boil out. This service may be “site –specific”. Our field agents will call and access each individual job draw up a method statement and provide all the documentation necessary to carry out the cleaning and passivation of your new boiler.

STERILISATION: Legionella bacteria are present in many water supplies and can thrive in cooling towers ,Storage Tanks and domestic water systems. Hydro-Jet Engineering and provide treatment methods to help control this potentially harmful bacteria.

Cooling towers are susceptible to high levels of Legionella bacteria due to their operating conditions and temperatures. Your biocide program may not be appropriate for the control of these bacteria. Additionally, domestic hot and cold water systems can allow Legionella to thrive. Hospital and Health-Care facilities can be at risk to Legionella growth due to lower hot water temperatures. A monitoring and control program should be in place to ensure a clean system.

Hydro Jet Engineering provide chlorination treatment service to water storage tanks and potable water systems.

Hydro Jet Engineering staff recognizes the dangers working with corrosive chemical.

All operators are trained in the handling of Hazardous chemicals and hold Haz-chem license for the transportation of chemicals by road.

We also operate a bulk Liquid waste management (see Liquid waste Management) Service and a confined space entry and tank cleaning service. Operators are trained in the use of Breathing Apparatus and working in Hazardous environments.

Mechanical Services

Hydro jet staff and operatives are trained and certified to carry out the work, which ensures we maintain all relevant safety standards at all times. We have, over 37 years, and have worked on all types commercial and industrial installations throughout the Republic and Northern Ireland. We can provide supervisors and operatives specifically trained to work on Maintenance and repairs water supply and water pumping water equipment

Hydro jet staff and operatives are trained and certified to carry out the work, which ensures we maintain all relevant safety standards at all times. We have, over 37 years, and have worked on all types commercial and industrial installations throughout the Republic and Northern Ireland. We can provide supervisors and operatives specifically trained to work on Maintenance and repairs water supply and water pumping water equipmentTypical Applications for Hydro Jet’s Mechanical Services:

• Supply and fitting of buster pumps

• Supply and fitting of pressure vessels and storage tanks.

• Boiler refractory repairs and replacement.

• Preparation of boilers for annual insurance inspection.

Benefits of the Hydro Jet’s Mechanical Services:

• Safe working practices, Quality Assured to meets all relevant Safety Standards

• Fast 24-hour service

• Trained experienced managers, supervisors and operatives

• Training includes operating with Breathing apparatus and working in confined spaces